|

|||||||||||||||||||||||||||||||||

Intoduction

The VELO will be installed as a pre-assembly in cavern UX85 at point 8. Geometry data:

Material data:

Material: AISI 304 Young's modules: 210 [GPa] Poisons ratio: 0.33 Yield Strength: 180 [MPa] Ultimate Strength: 460 [MPa] Density: 7.85 [g/cm3] FEA data:

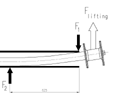

Mesh type(s): 3D Solid parabolic tetrahedron Savety constrains: load lifted by only two points (4 points available) Safety factor = 2.4 Load(s): Weight 2 Detectors = 4000 [N] Weight Vacuum Vessel = 10000 [N] Weight Stand = 6000 [N] Weight mechanics = 6000 [N] + ------------------ Total weight VELO = 26000 [N] Flifting = (26000/2)/cos19 * 2.4 = 33000 N F1=Flifting= 33000 [N] F2= reaction force from the lifting rod1) Moment of inertia: I = phi * d4 / 64 = 306,796 mm4 Deflection: f = 6.2 - 4 = 2.2 mm F2 = ( 3 * E * I * f ) / l3 = 1742 N Type of Solution: Linear Statics Units: Length [mm]; Force [N]; Stress/Pressure [Mpa]

|

|

||||||||||||||||||||||||||||||||

|

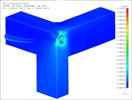

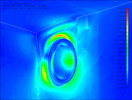

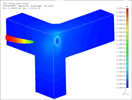

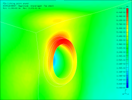

RESULTS:

SUMMERY: max Stress (Von Mises) = 172 MPa max displacement = 0.38 mm |

|||||||||||||||||||||||||||||||||

|

CONCLUSION:

Max Stress of 172 MPa2) is below the yield strength (180 MPa), so still elastic.

| |||||||||||||||||||||||||||||||||

NOTES:

space (=4 mm) in between, so this will cause the force [F2] on the tube 2) Note that for the load, the safety factors are taken into account |

|||||||||||||||||||||||||||||||||