Copyright (c) Nikhef. All rights reserved.

On this page the production of the Velo upgrade is displayed.

Bare module production

- Sample of Bare Module Gluing (MP4)

This bare module is constructed with a dummy silicon substrate and a replacement connector. This was done to test the jig and see what needs be improved. But it's a good movie to get the idea for bare module production. The real production time will be slightly less.

Documents last updated 19-09-2017

/EdgeCam/thumbs/4.jpg)

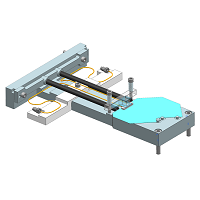

RF-box

- Documentation and photos

Left A-side half box H1 half left side box foil large angle wallthickness 500 um (2015)

Left A-side half box H2 milled wallthickness thin part 250 um, overall wallthickness 500 um (2016)

Left A-side box A1 milled wallthickness 500 um, wallthickness thin part is etched down (2016-2017)

Left A-side box A2 milled wallthickness thin part 250 um, overall wallthickness 500 um (2017-2018)

Alumnium mold C-side box (2017)

Right C-side box C0 (formerly known as C1) is discarded due to alignment error which caused an major error during the milling process (2018)

Right C-side box C1 milled wallthickness thin part 250 um, overall wallthickness 500 um; This box is under construction (21-09-2018)

Documents last updated 23-10-2018